Sustainability: no half measures.

How SEHON makes bodyshops and paint stores fit for the long term.

The Swabian paint shop manufacturer is regarded as a leading specialist when it comes to implementing sustainability goals in body and paint stores.

Tiemo Sehon shows where the best opportunities lie for companies and which mistakes can be avoided.

Ever since Sehon developed the first energy-saving module for paint booths in 1998, sustainability, energy saving and environmental protection have been firmly anchored in the manufacturer’s corporate philosophy.

In over 25 years, Sehon has continued to perfect green technology through its own research and development, so that customers can now benefit from maximum expertise in the implementation of sustainability strategies.

No half measures

For Tiemo Sehon, one thing is certain: “The term sustainability is overused in general and in our industry. Everyone and everything is suddenly sustainable. No wonder that in some places the use of LED lighting is already being celebrated as a milestone in sustainability. But this is the wrong approach. Making small adjustments does not really make a company fit. The decisive factor is that operational sustainability must be viewed, planned and implemented as a whole. Because sustainability will be with us for the long term. Those who do not think and work sustainably in the future will unfortunately not be among the winners over time.”

For Sehon, effective and successful sustainability strategies consist of a package of interrelated, interlocking measures that need to be carefully planned and implemented for both new builds and the modernization of businesses.

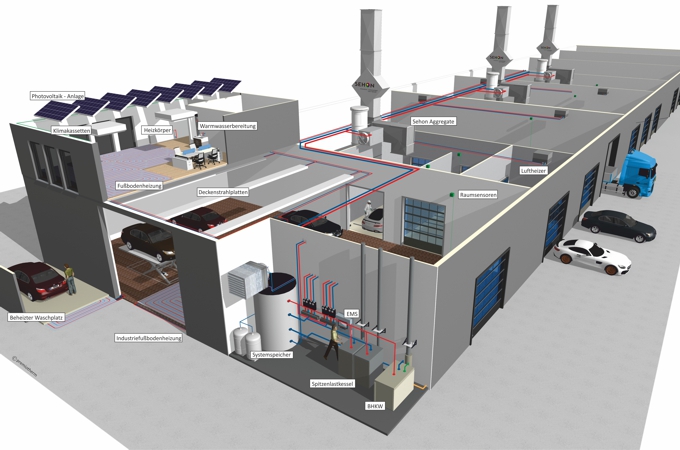

Individual energy-saving measures in a body and paint store.

The most important of these are photovoltaics and CHP with the greatest energy-saving potential.

Sustainability booster

“The biggest sustainability boosters,” says Tiemo Sehon, “are and remain renewable energies such as hydropower, solar and wind energy, biomass and geothermal energy.

Companies need to check which of these energies are available and can be integrated on site.

Experience has shown that photovoltaics is the easiest to implement for most companies.

We are able to use all regenerative forms of energy with our system technology.

Sehon will be the first body and paint store in Bavaria to obtain all of its energy from geothermal energy and photovoltaics, making it the first company to operate in an absolutely CO₂-neutral manner”.

Energy-saving technologies such as CHP units and heat pumps should be used as further effective sustainability measures.

With these technologies – with or without a connection to renewable forms of energy – significant energy savings can be achieved that can lead to energy self-sufficiency.

Energy management and energy monitoring for the entire company.

An important building block for significant energy savings, an in-house combined heat and power plant.

Have energy savings confirmed

Over the past ten years, Sehon has primarily focused on sustainable spray booths for customers and interested parties.

Energy savings of up to 80 % compared to traditional booth technologies from other suppliers have been achieved with Sehon technology, both then and now.

Anyone who wants to build or modernize their business should always ask the respective system manufacturer to confirm in writing in figures, data and facts how high the energy savings actually are.

It is not uncommon for companies to be verbally promised energy saving potentials that are not achieved in practice.

“Tiemo Sehon explains: “What’s unique in our industry is that we already record in writing in our quotations what energy savings the company will actually achieve with our technology.

With our life cycle cost documentation (LCC) in accordance with DIN standards, we can also check retrospectively whether our systems and measures have achieved the desired savings.

In all projects, we have achieved the targets set out in writing in our LCC, and in many cases even exceeded them.”

State funding and financing

Why is written documentation and confirmation important in the run-up to sustainability measures?

There are two key reasons for this.

Firstly, Sehon’s principle is to achieve maximum state support for the customer.

Secondly, Sehon LCCs are extremely welcome at banks, where they serve as a basis for financing.

Tiemo Sehon comments: “We are dealing with important customer funds. We cannot do things by halves and must not work with approximate figures, estimates or empty promises. It is often overlooked that development banks can check retrospectively whether the subsidized savings are actually achieved in practice. In any case, we do not want the companies we support to have to pay back the subsidies they have received. And that has never happened.”

Tiemo Sehon, CEO of Sehon innovative paint systems.

A welcome speaker on the subject of sustainability in the industry.

Saves energy and resources.

Spotrepair on multi-workstations from Sehon.

Change behavior.

Take temperature, for example.

For Sehon, it is clear that behavior in companies must also change.

There is no point in continuing to work as before despite all the energy-saving technology available.

Sehon cites the temperatures of paint booths and dryers as a typical example.

In the private sector, owners, managers and employees know that simply turning down the heating temperature reduces energy costs enormously.

In private households, one degree less than 20 °C = 6 % cost savings, 2 degrees less = 11 % savings and 4 degrees = 24 % less heating costs.

Logically, the same applies to operation.

Contrary to popular belief, however, most of the energy in the painting and drying system is not consumed during drying, but during painting.

Depending on the system characteristics and technology, the dryer only consumes around 20 % of the energy, whereas the spray booth consumes around 80 %.

Sehon has calculated that every degree of heat that can be saved in the paint booth saves around EUR 3600 per year.

This money could be used to operate a dryer for a year.

The importance of modern coatings

New modern self-drying or moisture-curing paints require much less or no drying energy.

And despite the use of these paints, many K&L companies continue to work in the paint shop as if nothing had happened.

Sehon has noticed that drying temperatures are often not adjusted, which would be urgently necessary and sensible.

The Sehon Managing Director believes that the coatings industry still has a duty to support companies over a longer period of time when switching to new coatings.

Repair instead of replace

Everyone in the industry now knows that repairing paint damage using spot repair is absolutely resource-saving and sustainable.

Components are repaired directly on the vehicle for small to medium paint damage without replacing the components with new ones.

Since 2012, Sehon has been offering the Multi-Speed-Master, a professional spot repair system that can be easily retrofitted in any workshop and meets all legal requirements.

In November last year, the European Parliament in Strasbourg adopted its position on the enhanced “right to repair” by an overwhelming majority.

During the warranty period, sellers would be obliged to repair instead of replace if a repair costs the same or less – unless the repair is not feasible or unfavorable for the consumer.

With the “right to repair”, the EU Parliament is primarily targeting consumer goods, but points out in this context that 77% of the EU population prefer a repair to a new purchase.

This means that “repair instead of replace” is a sustainability criterion that should not be underestimated and is extremely popular with customers.

Sehon therefore recommends – if it has not already done so – that spot repairs are increasingly included in the range of body and paint services.

This measure is sales-promoting, effective advertising and good for the bodyshop’s image.

Compressed air treatment

There is no doubt among experts about the benefits and effectiveness of professional compressed air treatment.

It is undisputed that filtering the spray air, heating it and ionizing it leads to less paint consumption, less reworking and longer throughput times.

The Aircommander from Sehon combines all the functions of modern spray air treatment in a single device and is connected between the compressor and the spray gun.

The savings in finishing are between 20 % and 40 %.

The flash-off and drying times are reduced by 10 % and 35 % respectively.

Depending on the paint, the paint savings are between 10 % and 20 %.

Anyone can calculate the savings in EUR for their own business.

The return on investment for the Aircommander is between nine and fifteen months, depending on the operating conditions.

After that, the device earns money for the paint store every day.

That is why Sehon recommends that sustainability-oriented companies invest in professional compressed air treatment, logically in the Aircommander.

What needs to be done?

For Sehon, paint systems are an important building block for sustainability in companies.

Sustainable, environmentally friendly and energy-saving paint systems are at least as important.

“I am fully convinced,” says Tiemo Sehon, “that companies need professional support for both new construction and modernization. How is the individual company supposed to know what is possible nowadays in order to be sustainable and future-proof? Questions upon questions: What is supported? What is important for my business? And above all: Who can implement my sustainability goals in practice? – Sehon can do that. Reliable, experienced and competent. Not just for paint shops, but holistically, i.e. for the entire body and paint store.”

Contact: sehon-lackieranlagen.de | info@sehon.de