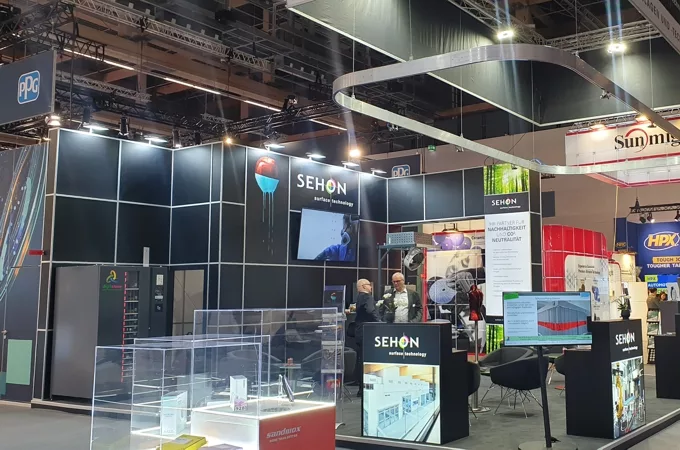

SEHON: Successful Automechanika 2024

The Swabian paint shop manufacturer presented its range of products and services relating to high-tech paint booths, sustainability and workshop equipment at this year’s Automechanika.

“Automechanika was a complete success for us,” says Tiemo Sehon, summarizing his company’s appearance at the trade fair, “we had interested parties and customers from Germany and abroad at our stand almost around the clock, informing themselves about cutting-edge technology, future technologies, problem solutions and trends in paint systems. Our visitors included body and paint stores, workshops, paint manufacturers, car manufacturers and global players in workshop equipment.”

Painting systems – high-tech + sustainability perfectly combined

The company has been one of the leading system manufacturers in the industry for many years and implements cutting-edge technology with maximum sustainability for its customers.

The energy-saving concepts for paint shops and paint stores attracted a great deal of interest at the trade fair.

One focus here was not only to make the paint booths energy-saving, but also to plan and implement the entire operation as sustainably as possible.

Tiemo Sehon: “With us, customers can be sure that top quality and the best possible sustainability are perfectly implemented. Above all, customers are impressed by the fact that we can point to great reference projects that have realized green paint stores and energy-saving paint stores with us. We are currently the first company to cover its energy requirements with geothermal energy. This is a clear example of our technology and innovative strength, of which we are particularly proud.

Demand for the energy-efficient refurbishment of existing paint stores and paint stores was also remarkably high at SEHON.

For this purpose, the manufacturer offers a comprehensive package of measures, retrofits and products that can be used to retrofit not only its own brand systems, but also most third-party products in a sustainable and energy-saving manner.

A key point for retrofitting companies is the question of which subsidies can be used to finance the energy measures.

Depending on the initial situation, SEHON guarantees its customers maximum funding and a quick return on investment, which is documented to the customer in writing and verifiably by means of precise profitability calculations before the order is placed.

E-vehicles – Comprehensive program for repairs

At Automechanika, manufacturer CAMELEON SYSTEMS presented a comprehensive program for the safe handling and processing of electric vehicles and multi-material mix bodies.

“Repairing electric vehicles,” says Tiemo Sehon, “requires workstations and workshop equipment that protect employees and the company from potential hazards. We don’t believe in scaremongering, but companies should equip themselves so that they can handle e-vehicles in accordance with legal requirements and regulations. With CAMELEON, we also want to ensure that our customers have access to a complete program for e-vehicles and do not have to laboriously gather the necessary equipment on the market.

CAMELEON SYSTEMS was nominated for the Automechanika Innovation Award.

This is a great success for SEHON, as the company is one of the 40 or so most innovative exhibitors among the approximately 4,200 exhibitors.

Anyone interested in the topic of “repairing electric vehicles” was able to take part in a workshop of the same name during the trade fair.

Intelligent storage with high savings potential

SEHON presented its DigitStore automated digital storage system to a wide audience for the first time at Automechanika.

DigitStore is a vending machine module for the controlled storage, goods issue and warehouse management of small parts and consumables in industrial, commercial and trade businesses.

By using DigitStore, material consumption can be reduced by up to 50%.

The integrated software provides a permanent overview of stocks and goods withdrawals.

Evaluations for management, purchasing, accounting or controlling are created in real time.

If required, orders can be placed directly with the suppliers of the goods and parts in the DigitStore.

Access to the DigitStore is via personalized access cards so that materials can only be removed by authorized employees.

Overall, the time and organizational effort for material procurement and material removal is reduced to a minimum.

In addition, access to spare parts and consumables is possible around the clock, regardless of working hours and the presence of warehouse employees.