Maximum performance

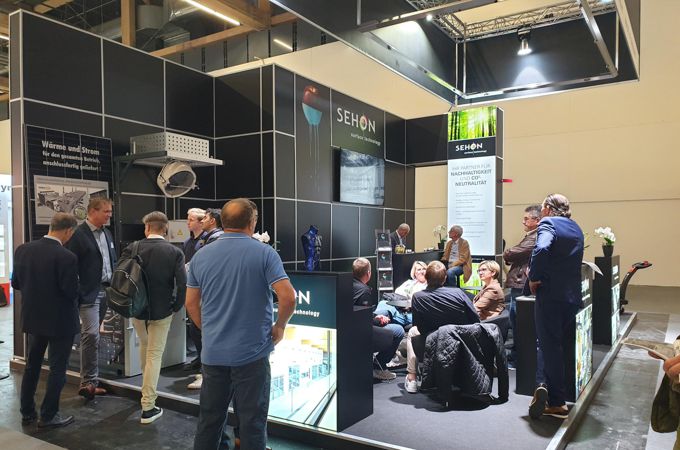

SEHON innovations at the Automechanika 2022

At Automechanika, SEHON presented a whole range of new products and innovations relating to energy, quality, efficiency and cost-effectiveness in bodyshops and paint stores.

Focus on energy

The focus of the SEHON presentation was on customized energy concepts, energy saving, energy optimization, energy-efficient refurbishment and sustainability in K&L operations.

The company offers a wide range of products and services for the new construction, conversion and modernization of paint stores and paint systems.

This includes energy-saving unit technology, year-round heat recovery with consistently high efficiency, mode-dependent energy management, various energy-saving modules, high-performance filter systems, LED lighting, intelligent control systems and the integration of renewable and alternative forms of energy.

According to Tiemo Sehon, these are just some of the features that can reduce customers’ energy costs and increase quality at the same time: “Starting from the symbiosis of high-tech and green technology in plant engineering, we have continuously developed the efficient and energy-saving energy supply of paint stores with our system partners. Today, we offer heat and power solutions for the entire operation (process systems, hall areas, office areas). Energy-saving and sustainable up to complete energy self-sufficiency.”

The Swabian system manufacturer offers a complete service.

This includes, for example, the initial consultation, the assessment of the energy situation, the creation of an energy concept, a profitability calculation, obtaining permits, the coordination of ancillary trades, the installation of the new energy center, operator training, system monitoring as well as maintenance and service.

Depending on the budget, technical requirements and individual wishes, SEHON customers save up to 60%, 80% and more energy.

Some companies even achieve energy self-sufficiency, i.e. they can feed the surplus energy generated during operation back into the power grid.

It is important for SEHON to be able to name reference companies where the energy concepts offered have been successfully implemented.

The new paint and bodywork center of the Graf Hardenberg car dealership group in Karlsruhe, equipped by SEHON, is a role model for sustainability.

There, 100% of the electricity and 75% of the heat energy is produced in-house, meaning it does not have to be bought in.

Another positive effect: the company saves around 380 tons of CO₂ every year.

SEHON also specializes in the energy-efficient refurbishment of existing systems – including non-Sehon systems (third-party brands).

Tiemo Sehon explains: “As every body and paint store is very individual, an on-site assessment of the current situation is necessary in each individual case. Ultimately, it’s not just about savings, but also about an investment. And it’s about possible subsidies that can be used to co-finance the energy-saving measures.”

CAMELEON PREMIUM bodywork workstation.

Microfine humidification of spray booths.

New bodywork workstations – on the safe side

SEHON has further expanded its CAMELEON body workstation range.

The well-known flagship CAMELEON PREMIUM has been expanded to include the ECONOMY and E-STATION models.

ECONOMY is the lower-priced version of the high-end PREMIUM model.

E-STATION is a special workstation for e-mobility.

The new price and budget-oriented but fully functional and safe CAMELEON variant ECONOMY for 1, 2 or multi-station solutions should be of particular interest to many bodyshops and paint stores.

A significant difference to the Premium model is that the extraction and safety technology is not permanently installed, but is instead provided by mobile devices.

Car bodies today are made from a combination of different materials such as steel, aluminum, carbon, magnesium or plastic.

Whereas car bodies used to be made exclusively of steel, the proportion is now less than 50%.

There are high safety requirements for working with different materials.

Improper handling of compounds such as steel, aluminum and carbon can not only lead to contact corrosion on the vehicle, but also to hazardous dusts, vapors and other chemical-physical compounds.

Tiemo Sehon: “CAMELEON is the safe and functional solution for all work on steel, aluminum or multi-material mix bodies in order not to harm the health of employees, to ensure safety in the workplace and to protect operations. With CAMELEON, not only steel bodies, but also bodies made of aluminum or in mixed constructions can be processed ergonomically, economically and, above all, safely at a single workstation without any loss of time.”

New SE-HYDROPLUS humidification system

SE-HYDROPLUS is the new innovative humidification system from SEHON for paint shops, dryers, preparation stations and post-reaction rooms.

SEHON sees its system as a microfine and cost-effective alternative to traditional steam humidification.

SEHON lists the following advantages:

- Dust-free due to the hydrosation of the process air

- Possibility of adding antistatic fluid

- Cooling effect in the effective area due to evaporative cooling

- Advantages when curing paint coats, both basecoat and clearcoat

- Quick switch-off and switch-on of moisture

- Monitored and adjustable humidification process using sensors, controllers and PLC control

- Frequency processing for better function and well-being of the user

- Remote maintenance option

SE-HYDROPLUS works in combination with the well-known SEHON Airplus system and / or with hydrosation over the entire surface using special ultra-fine nozzles.

Although tap water is the most monitored foodstuff, its quality and composition is not sufficient for use in painting processes (e.g. due to limescale and other deposits).

Process water – regardless of the type of humidification – must therefore be desalinated and demineralized beforehand.

Optionally, SE-HYDROPLUS water can be sterilized, antibacterially treated and / or frequency-adjusted.

Pure water through osmosis and sterilization!

SE-HYDROPLUS can be used in almost all rooms of a body and paint store to optimize the climate.

Retrofitting with SE-HYDROPLUS is not only possible for all existing SEHON systems (with and without SE-AIRPLUS), but also for third-party brands.

New SE-MOVE IT transport and maneuvering system

SEHON MOVE IT is a new innovative transportation and manoeuvring system for cars and vans.

It allows vehicles in workshops, body and paint stores, car dealerships and showrooms to be moved from A to B conveniently and emission-free (zero emissions).

The system is available in different versions for manual or electrically powered vehicle shunting (pulling and pushing).

The vehicle can be moved in all directions, both lengthways and crossways.

Operation takes place at the ergonomically correct, comfortable height.

Compared to existing shunting products, SEHON sees its system as a particularly cost-effective, sustainable, convenient and universal transportation and shunting solution that can be used in practically any business without any problems.

Successful trade fair

Tiemo Sehon (CEO) is satisfied with the results of the trade fair: “Automechanika was a huge success for us. The very strong visitor interest and the many discussions with customers have confirmed that we are once again contributing to the success of our customers with our products, ideas and concepts and helping to further develop the industry and make it future-proof. We always offer maximum performance and are a little proud that many of our customers see us as the industry’s leading think tank. For us, this is both a motivation and an obligation to further extend our technological lead.”

“We take care of issues,” Tiemo Sehon continues, “that many other manufacturers cannot do to the same extent. It is perfectly normal for us to see ourselves as an integrative partner who is involved right from the preliminary planning stage, in discussions with architects and in energy and process management, contributing important expertise in the process.”

When purchasing a paint shop, the importance of complying with legal regulations, guidelines and standards is often overlooked.

If these are disregarded or not adhered to, the paint store is entering unsafe territory because the company and its employees are permanently at risk.

This is because the company owner is liable for operational safety.

This is why SEHON ensures that its systems comply with legal requirements.

According to Tiemo Sehon, some providers only pay lip service to this, but at SEHON it is a transparent and comprehensible plus.

For a paint store, the purchase of a paint shop, as well as its modernization, is not an everyday task.

A company owner is often only confronted with this once or twice in their working life.

It is therefore important to bring yourself up to date before making a purchase and to find out which partner offers the best overall concept and the best possible technology in order to provide optimum support for the upcoming project from A to Z.

According to Tiemo Sehon, his company offers the best conditions for this and over 40 years of experience: “For our customers from trade, industry and the automotive sector, we are an absolutely reliable partner for all issues relating to new builds, conversions and modernization. We create the perfect symbiosis of high-tech and green technology in every business. In an all-round carefree package, with a high degree of future security.”

Contact: sehon-lackieranlagen.de | info@sehon.de

Author: Michael Teschke, September 14, 2022 | Photos: Sehon